Vibration testing is used to assess the resistance and reliability of products when subjected to dynamic stresses. During these tests, real usage conditions or “extreme conditions” that the products may encounter are simulated. To conduct vibration tests, INTEK offers a dedicated testing area equipped with a high-speed camera and various accelerometers.

- Measuring Vibrations to Assess Resistance

- Vibration Testing: A Quality Assurance for Various Sectors

- Standards and Reference Guidelines

- Case Study: Vibrations in the Transportation of Electrical Materials

- INTEK Services for Vibration Testing

- State-of-the-Art Laboratory for Testing

- INTEK custom vibration tests

Measuring Vibrations to Assess Resistance

As is easily understandable, vibrations can significantly influence the durability of products. During tests, sinusoidal, random, or impulse vibrations can be generated depending on the applications and environments in which the products are expected to be used. At this stage, the responses of the product are monitored, and any anomalies or damages are evaluated.

The INTEK laboratory is capable of performing vibration and shock tests in accordance with major international standards. With cutting-edge equipment, INTEK can test any type of component.

Vibration Testing: A Quality Assurance for Various Sectors

Vibration tests are applied in a wide range of sectors, including the automotive, aerospace, and electronics industries, among others. These tests are essential to ensure the quality and reliability of devices. Thanks to the ability to simulate real usage conditions, potential problems can be identified and resolved before they occur in operational contexts.

Standards and Reference Guidelines

Vibration tests are regulated by specific standards and guidelines, including ISO 16750 for the automotive industry and IEC 60068-2-x standards for the electronics industry. These standards establish test requirements, procedures, and evaluation criteria to ensure product compliance and safety.

Case Study: Vibrations in the Transportation of Electrical Materials

Vibration tests, as defined by the IEC 60068-2-64 standard, are fundamental for evaluating the resistance of electrical and electronic devices during transportation. During such tests, particular attention is paid to the condition of screw terminals, for example, which may tighten due to vibrations, causing inconveniences for installers who need to reopen them to connect wires.

INTEK Services for Vibration Testing

The INTEK laboratory is ACCREDIA accredited for performing vibration tests in accordance with various standards, including IEC 60068-2-64 for broadband random vibrations, IEC 60068-2-6 for sinusoidal vibrations, IEC 60068-2-27 for shocks, and IEC 60068-2-80 for mixed-mode vibrations.

The INTEK laboratory is also equipped to assess the heat resistance of a wide range of materials through Glow-Wire Testing.

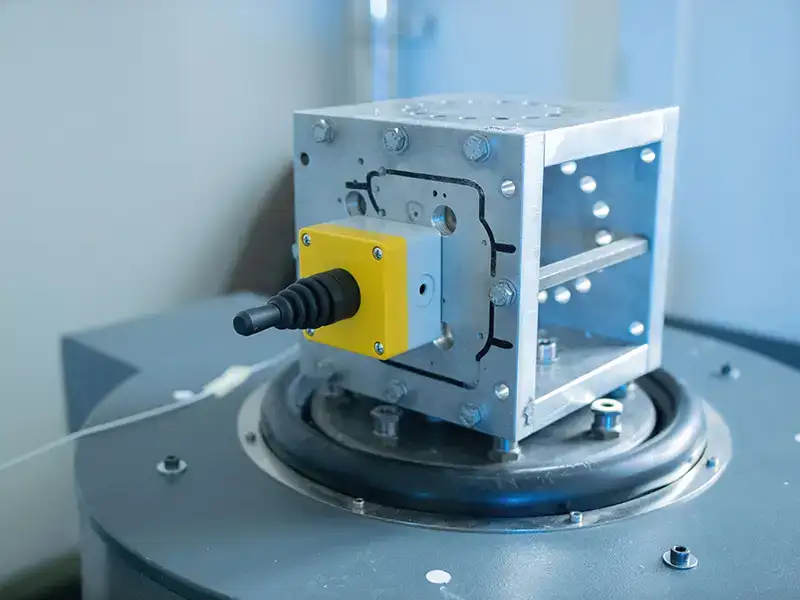

State-of-the-Art Laboratory for Testing

Measuring vibration is essential to understand and manage the mechanical phenomena that affect product stability. INTEK uses advanced instruments, such as the powerful Belotti Shaker L Series system and the sophisticated Phantom MiroLab110 high-speed camera, to ensure unparalleled precision in assessments.

Here are the technical specifications of the Belotti Shaker L Series system used in tests:

- Sinusoidal and random force: 10 kN

- Shock force: 20 kN

- Maximum static load: 200 kg

- Frequency range: 5-3500 Hz

- Speed: 2 m/sec, stroke 51 mm

Additionally, the Phantom MiroLab110 high-speed camera offers high-level performance:

- Maximum resolution: 1280×800

- Maximum frame rate: 20,000 fps

- Maximum frame rate at maximum resolution: 1600 fps

- Pixel pitch: 20 μm

Thanks to these technologies, INTEK is able to conduct extremely reliable vibration tests and ensure high-quality results for its clients.

INTEK custom vibration tests

Every device has its own specific requirements. This is precisely why INTEK is able to offer customised vibration tests. By simulating the mechanical stresses a device experiences during transport, installation and use, potential reliability problems can be identified and resolved. Precise measurement of the data collected during vibration tests provides a complete picture to optimize product longevity and production processes.

Download the PDF about INTEK Vibration Testing: Tests under Real Usage Conditions.

How can we help you?

Enter your details below and select the type of request.

One of our experts will contact you to provide all the information you require.