ATEX testing is a crucial step to ensure the safety and compliance of devices used in potentially explosive environments. These tests aim to evaluate the reliability and safety of the equipment, reducing the risk of workplace accidents. INTEK offers specialized services to conduct these tests, guaranteeing device compliance with the highest safety standards.

ATEX Certification According to EU Directives

ATEX certification confirms the compliance of products intended for use in environments where there is a risk of explosions. Regulated by the European ATEX directives (Atmosphères Explosibles), it ensures that these devices are designed and built to prevent and protect against explosions caused by flammable gases, vapors, or dust. To obtain ATEX certification, procedures are defined that, depending on the level of risk, may require the involvement of a third-party Notified Body (ExNB).

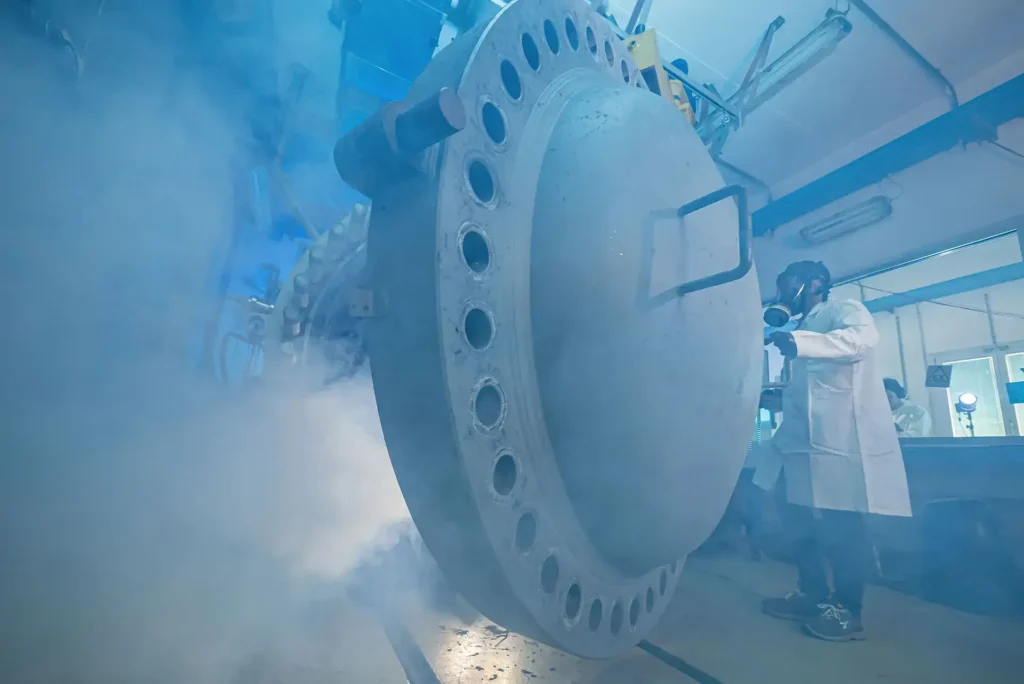

In the INTEK explosion laboratory, tests are conducted in compliance with the ATEX directive. All sensors for overpressure measurements have been specifically developed on an exclusive INTEK design.

How to Obtain ATEX Certification

The process to obtain ATEX certification requires the execution of specific tests. These tests are essential to identify and resolve any design or production defects that could jeopardize the safety of operators and facilities. Once these tests are passed, the devices are considered compliant with safety standards and can be marketed in the European Union.

Reference Standards for ATEX Testing

ATEX tests are regulated by the European directive 2014/34/EU. It covers electrical and non-electrical (mechanical) products intended to be installed in explosive atmospheres (gas/dust) that present potential ignition sources for explosions, which may become active. The use of Harmonized Standards from the EN IEC 60079 series (electrical products) and EN ISO 80079 (mechanical products) ensures presumption of conformity with the Directive.

INTEK: Specialized Services for ATEX Testing

INTEK offers a wide range of ATEX testing services, including resistance tests to explosive agents and device certification. INTEK is ACCREDIA accredited for conducting ATEX tests in accordance with Harmonized Standards. They specialize in regulatory support and laboratory tests in compliance with directive 2014/34/EU of the EN 60079 and EN 80079 series. Additionally, they perform tests according to the IEC 60079 series for the IECEx scheme.

To better evaluate the electrical safety of devices, INTEK also conducts Short Circuit Tests.

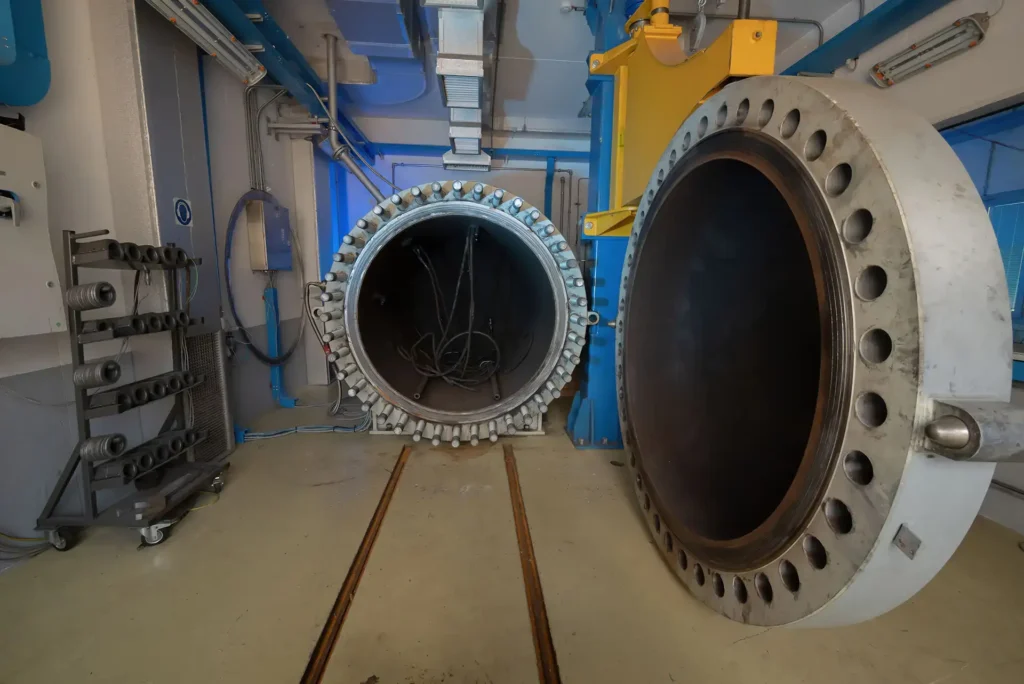

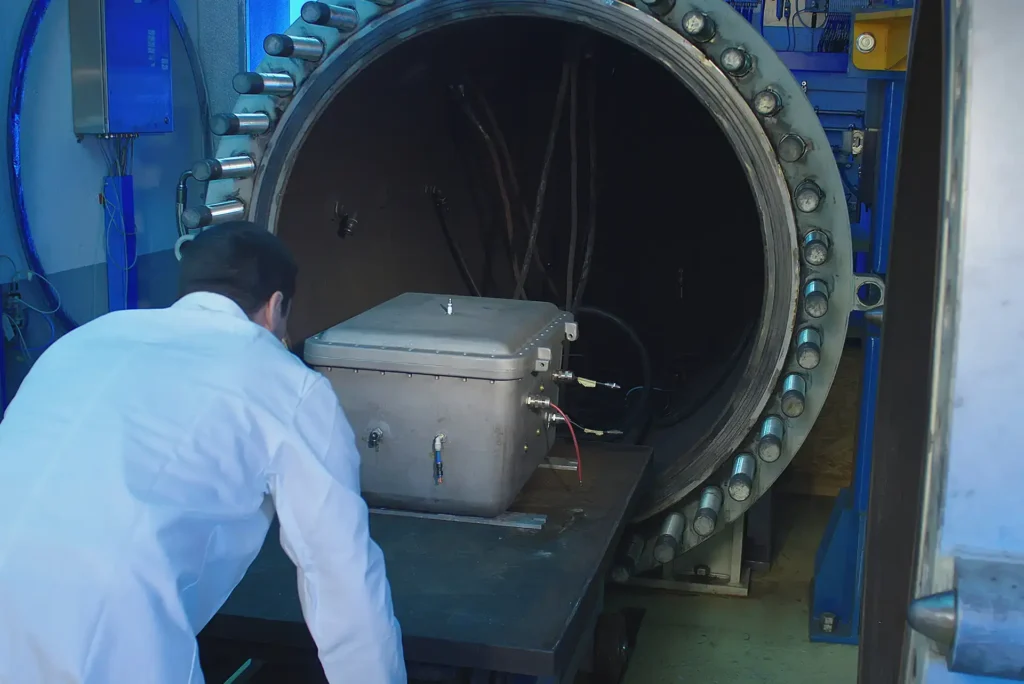

INTEK ATEX Testing Laboratory

The INTEK Laboratory is equipped with an ATEX testing chamber with a volume of approximately 2 m³ and can accommodate equipment up to 1000 x 1000 x 2000 mm. It can power devices with voltages up to 800 V in three-phase and a maximum current of 100 A. The gas control and mixing system is designed to create normative mixtures with oxygen and hydrogen, acetylene, ethylene, propane, or methane. The accuracy of the mixtures is verified using sample mixtures through a gas chromatograph.

Download the PDF about INTEK ATEX Testing for Products in Explosion-Risk Environments service.

How can we help you?

Enter your details below and select the type of request.

One of our experts will contact you to provide all the information you require.