Salt spray tests are standardized procedures used to evaluate the corrosion resistance of materials and surface coatings. INTEK’s salt spray testing procedures involve exposing products to simulated corrosive conditions to assess their resistance to harsh environments.

Salt Spray to Simulate Corrosion

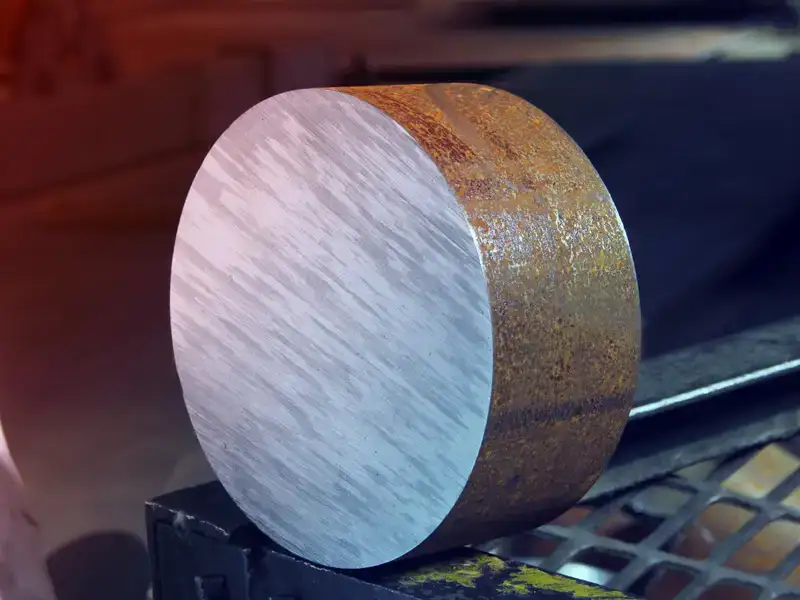

Neutral salt spray is a solution of water and sodium chloride (NaCl) used to recreate accelerated corrosion conditions. Salt spray tests are significant because they allow for the assessment of materials’ corrosion resistance in a relatively short period. This enables manufacturers to identify potential issues and improve product durability.

Salt Spray Test: Phases and Duration

During the salt spray testing procedure, the test samples are exposed to the solution within a specially designed chamber. This exposure occurs under constant conditions for a defined period. The duration can vary depending on the client’s specific needs and the material being tested. Generally, salt spray tests can last thousands of hours, simulating years of real-world exposure. At the end of the test period, samples are examined for any corrosion effects, discrepancies, or damages.

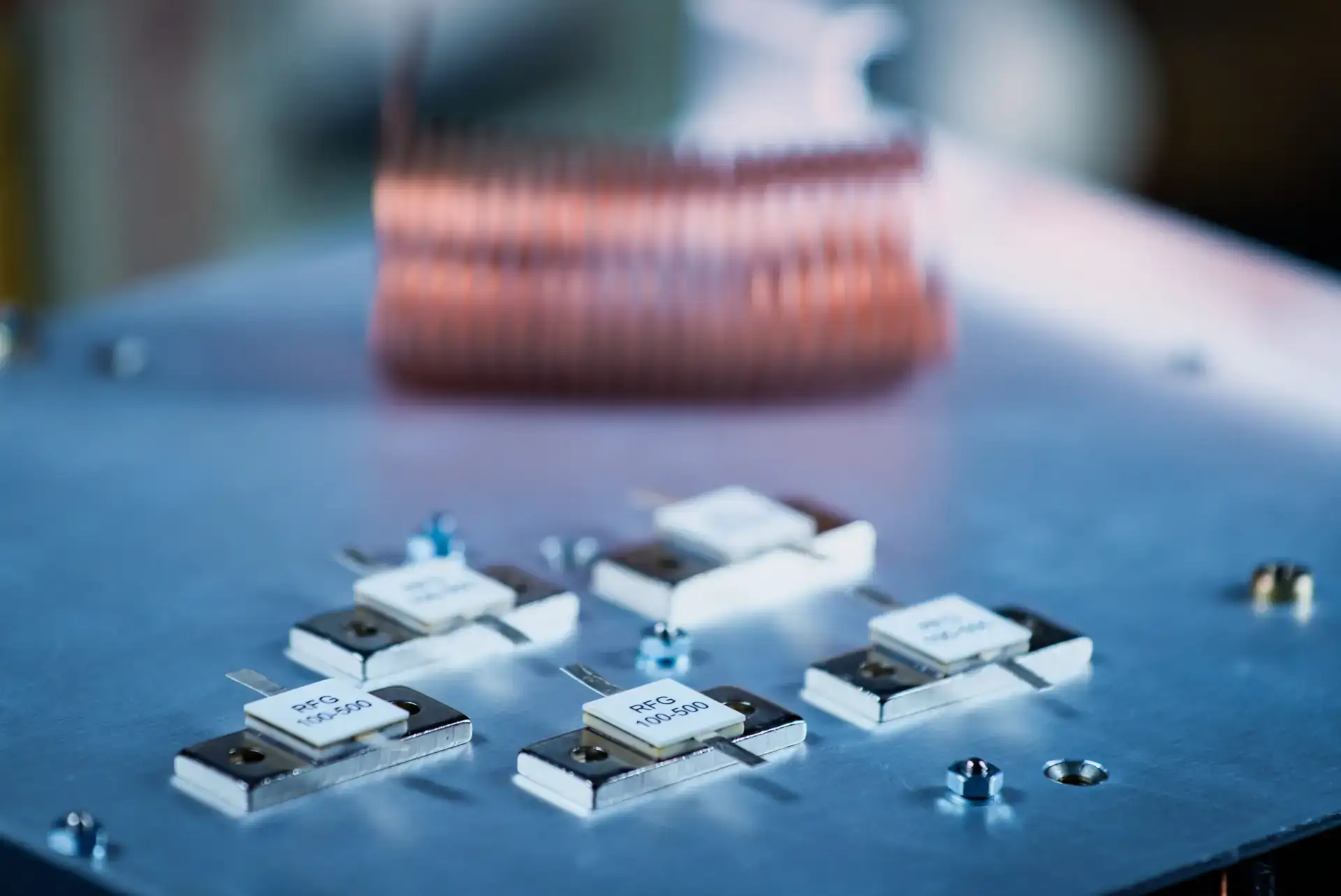

Salt spray materials corrosion testing

Undergoing salt spray corrosion tests on materials is a critical step in ensuring the longevity and reliability of products. By simulating the harshest conditions, corrosion tests on materials and surface coatings allow early identification of any inefficiencies, enabling modifications to be made to improve durability and prevent costly recalls.

Salt Spray Tests: Industries Involved

Salt spray tests are widely used in the manufacturing industry to assess the corrosion resistance of metallic materials, surface coatings, electronic components, and other parts. These tests are crucial for the maritime, automotive, aerospace, and electronics sectors, where they can significantly enhance product durability and reliability.

Corrosion Tests: ISO 9227 and EN 60068-2-11 Standards

Salt spray tests are regulated by a series of international standards and directives. Among these, ISO 9227 and EN 60068-2-11 standards set the reference protocols for corrosion tests, defining the procedures to follow and establishing evaluation criteria to ensure the compliance of products under analysis. These standardized protocols provide a reliable and uniform framework for assessing materials’ corrosion resistance, ensuring high-quality standards.

INTEK Salt Spray Testing Services

INTEK offers comprehensive and certified salt spray testing services, ensuring precise results in compliance with international standards. With extensive experience and a well-equipped laboratory for conducting these tests, INTEK supports clients from various industries in performing salt spray tests. Additionally, INTEK assists clients in interpreting the results to enhance product performance in terms of corrosion resistance.

As part of its resistance evaluation services, INTEK also conducts environmental and climatic tests.

Download the PDF about INTEK Salt Spray Testing: Corrosion Resistance Tests.

How can we help you?

Enter your details below and select the type of request.

One of our experts will contact you to provide all the information you require.